Precision automation. Actionable information.

The Doran FC6300 system is a durable, high-performance scale with best-in-class formula control software included — delivering performance and value from day one with ROI in just a few months. Throughout the weighing process, the FC6300 provides real-time data for real-time control — to lower ingredients costs, eliminate bad batches, add operator accountability and find efficiencies. Scaled formulas are saved as a digital record, which is far more accurate than the typical handwritten records used on most plant floors. Search and analyze production data quickly, and retrieve all batch data of a specific lot ID.

WHY INVEST IN A DORAN FC6300

Employee accountability

Ensure ingredients are within tolerance, gather data at every step of the process and track ID numbers, and generate reports to drive productivity.

Designed and engineered by industry experts

Doran precision scales and software set the standard for performance and reliability.

Traceability and compliance

Maintain BRC, FDA, FSMA and many other quality standards.

No experience needed

The equipment and software is easy to learn, easy to operate, and easy to maintain.

Reliable support

On-site support, installation and training provided by Doran specialists to ensure peak performance.

![]()

Beyond information, innovation

Doran ionSuite software is easy to configure and easy to operate — delivering real-time data to assess and manage every step of the process for pinpoint control.

Formula Loader software included.

Formula Loader is a complete formula control application that ensures precise formulations, validation to meet government regulations and QC certifications, and ingredient traceability. By delivering real-time data and access from any browser, operators and managers can improve accountability when creating a product manually or with a batching, dosing, or process control system.

ADDITIONAL SOFTWARE, OPTIONS AND SERVICES

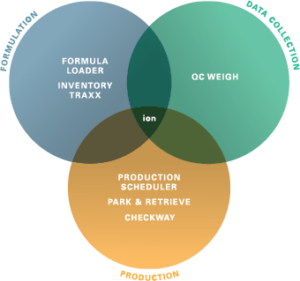

Formula Loader is part of the Doran ionSuite™ — six web-based software applications designed for precision formulation, real-time data collection, and efficient production.

Inventory Traxx

As batches are run on the scale, ingredient usage is tracked and inventory totals are updated, and ingredient Lot IDs are tracked in real-time. Avoid costly inventory control errors that affect budgeting, forecasting, resource allocation and strategies.

Production Scheduler

Removes production sheet and prompts operators through their shift. Supervisors can control the scales — changing tolerances, associating user IDs to scale IDs, assigning scales to groups or adding product IDs to scales.

Park & Retrieve

Full operational control and tracking across all devices involved in the formation of minor, micro, and bulk ingredients. Create a complete product record and maintain full traceability.

ERP, MRP integration. SQL standard.

Data is fully integrated with ERP, MRP and other enterprise software. All software utilizes SQL Express Database.

On-site support, installation and training.

Provided by Doran specialists or authorized Dealer.

Fast and accurate, with easy lot traceability.

By prompting the user through the formula, each ingredient is weighed within a user-defined tolerance and the correct ingredients are accurately scaled every time.

Specifications

| Warranty: | Two Years |

| Power: | 115 VAC, 50/60 Hz (230 VAC Optional) |

| Communications: | USB and Wired |

| Display: | LCD - 7" TFT LCD, 800 x 480 |

| Controls: | Clear, Enter, Start/Stop, Lot Id, Recall, Zero, Menu, F1, and Alphanumeric Keypad |

| Construction: | 304 Stainless Steel |

| Dimensions: | Indicator: 8" H x 10" W x 3.75" D |

| Base Sizes: | 8" x 8", 10" x 10", 12" x 12", 15" x 15", 18" x 18", 18" x 24", 24" x 24" |

| Weight capacity: | 1 g to 100,000 lb |

| Brackets: | U-bracket is standard |

| Columns: | 20" Column Standard and 30" Columns Available |

Options

| Ethernet Optional Communication: | Wireless Ethernet |

| Options: | Formula Loader software Stainless steel table Barcode scanners Label printers Onsite support, installation and training |

Explore the FC6300 with Doran CEO, Mark Podl

Mark Podl explains the individual components of the FC6300 formula control scale in this brief five minute video. You’ll see all the information that can be tracked and displayed on its big LCD display and see the detail of its rugged construction.