Specialized software. Scalable solutions.

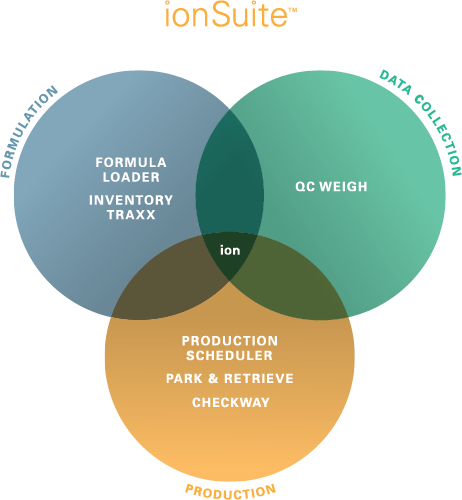

With innovative features and best-in-class performance, Doran ionSuite™ is designed to lower costs, achieve plant-wide efficiencies and ensure employee accountability. Maintain total control at every step of the production process — from formulation through packaging and traceability — to accurately project financial return on every batch.

The complete ionSuite is web-based, mobile compatible and accessible from any browser — or install applications on-premise and maintain them on-site.

Precise formulation

Manage inventories and program formulas to achieve efficiencies and product consistency. Reduce operator error and eliminate bad batches.

Real-time data collection

Collect, archive and retrieve data-driven production reports to drive quality control, track operator performance, reduce downtime and maintain accountability.

Efficient production

Collect data at every point in the production process — to see the big-picture, assess operations and maintain pinpoint control over the plant floor.

Beyond information, innovation.

Doran ionSuite software is easy to configure and easy to operate — delivering real-time data to assess and manage every step of the process.

Formula Loader

For precise formulations, validation to meet government regulations and QC certifications, and ingredient traceability. Improve accountability when creating a product manually or with a batching, dosing, or process control system. Included with the FC6300 Formula Control Scale and BC6500 Bulk Control Indicator.

Inventory Traxx

As batches are run on the scale, ingredient usage is tracked and inventory totals are updated, and ingredient Lot IDs are tracked in real-time. Avoid costly inventory control errors that affect budgeting, forecasting, resource allocation and strategies. Available for the FC6300 Formula Control Scale and BC6500 Bulk Control Indicator.

QC Weigh

Configure static checkweighers to follow QC processes, collect data and provide reporting on product weights and accuracy. Use unique operator IDs, scheduled sample intervals with alarms, and data collection to confirm quality control tasks.

Also, record all weighments on the factory floor and view performance by product, operator and line. Remotely manage employee productivity and control scales — changing tolerances, assigning scales to groups, or adding product ID’s.

Available for the 2200CW Checkweigher series.

Production Scheduler

Removes production sheet and prompts operators through their shift. Supervisors can control the scales — changing tolerances, associating user IDs to scale IDs, assigning scales to groups or adding product IDs to scales. Available for the FC6300 Formula Control Scale and BC6500 Bulk Control Indicator.

Park & Retrieve

Full operational control and tracking across all devices involved in the formation of minor, micro and bulk ingredients. Create a complete product record and maintain full traceability. Available for the FC6300 Formula Control Scale and BC6500 Bulk Control Indicator.

CheckWay

Easy-to-use controls for managing Product IDs and User IDs from a desktop or portable device with wired ethernet or wireless Internet access. Manage one scale or control multiple lines — replacing manual entry to deliver saving time, improving quality control and delivering cost savings. Available for the 2200CW Checkweigher series.

ionSUITE upgrades,

options & services

Upgrade software for the FC6300 Formula Control Scale and BC6500 Bulk Control Indicator to ionSuite versions for web-based functionality.

ERP, MRP integration. SQL standard. Doran can ensure that data is fully integrated with ERP, MRP and other enterprise software. All software utilizes SQL Express Database.

On-site support, installation and training — provided by Doran specialists.