Remote Control. Operator Accountability.

Performance ID can record all employee activity from a Doran 2200CW Checkweigher to provide real-time data on production performance by product, by operator and by line. Supervisors can manage employee productivity and control scales — changing tolerances, assigning scalesto groups, or adding product ID’s. Comprehensive reports show weighments per hour along with overall production accuracy by employee ID — to avoid underweight or overweight that can result in rejected shipments, fines or higher production costs. Accurate production data also aids management in rewarding employees based on speed, consistency, and productivity performance — and take corrective action to improve quality control.

KEY PERFORMANCE FEATURES INCLUDE

Real-time data collection and efficient production

Pinpoint control of the plant floor — from formulation through packaging and traceability.

Employee accountability

Gather data at every step of the process to ensure user-defined tolerances are met for each ingredient every time.

Desktop, laptop or mobile accessible with any browser

Communication connection with 2200CW include wired Ethernet, washdown safe Ethernet, Bluetooth or USB.

Cloud-based or install on premise

With access from internal systems.

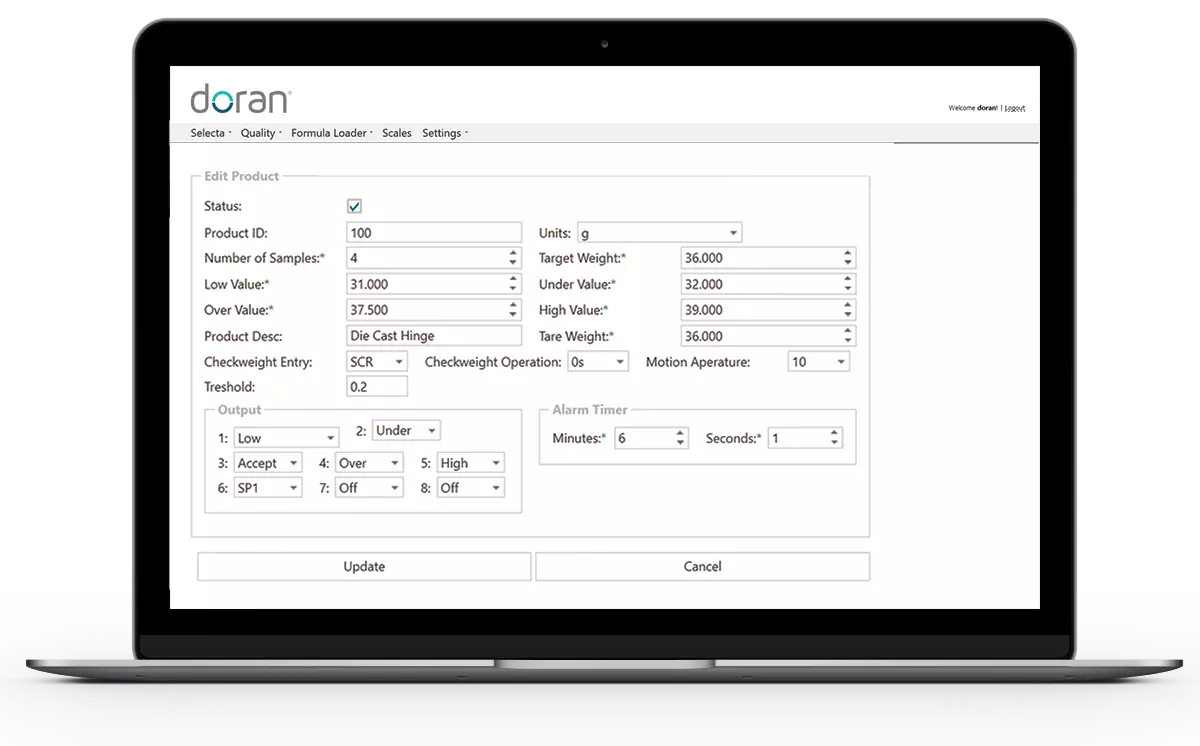

Effortless configuration

Configure Performance ID and the 2200CW with drop-down menus and easy-to-understand program prompts.

Configure several scales with identical data

Programming hundreds of product parameters takes minutes, instead of hours.

![]()

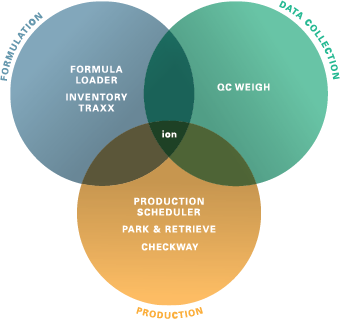

BEYOND INFORMATION, INNOVATION

Doran ionSuite software is easy to configure and easy to operate — delivering real-time data to assess and manage every step of the process for pinpoint control.

Exclusively for the Doran 2200CW Checkweigher Series

QC Weigh is exclusively for the 2200CW, a versatile checkweigher designed for speed and durability — with many configuration options.

Setup is fast and efficient. By adding Performance ID, management can create a database of products or SKUs and control production activity on one checkweigher or all checkweighers on a network. Production employees do not have access to scale buttons or scale features, so they are unable to alter target weights and tolerances or affect performance metrics. The 2200CW has memory for 800 product IDs and 200 user IDs.

PERFORMANCE ID

Setup screen allows for fast entry of weighing parameters and controls for each 2200CW checkweigher or for multiple checkweighers.

ADDITIONAL SOFTWARE AVAILABLE FOR 2200CW

QC Weigh software

Capture quality control data to ensure accurate product weights and meet QC benchmarks. Improve accountability, using unique operator ID’s and scheduled sample intervals to verify that employees are performing quality control tasks.

Enterprise software integration. SQL standard

Doran can ensure that data is fully integrated with Statistical Process Control (SPC) systems and other enterprise software. All software utilizes SQL Express Database.