Full-featured checkweigher. Technologically advanced.

The 2200CW SS Series is designed for speed, durability, and versatility — a smart choice for a range of weighing applications. Fast and accurate checkweighing to boost bottom line performance — by improving accuracy and decreasing shortages or giveaways. Add Doran QC Weigh software to automate and validate QC procedures, and improve production staff accountability. The system features a responsive keypad, rugged stainless steel construction, and IP69K classification for washdown protection — with components that are built in the USA. A large selection of Doran power options, scanners, and communications and networking equipment, and other accessories. Plus, add Doran ionSuite™, QC Weigh and Performance ID software for real-time data collection and efficient production.

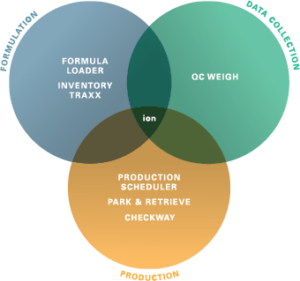

OPTIONAL DORAN SOFTWARE

QC Weigh

Configure static checkweighers to follow QC processes, collect data and provide reporting on product weights and accuracy. Use unique operator IDs, scheduled sample intervals with alarms, and data collection to confirm quality control tasks.

Also, record all weighments on the factory floor and view performance by product, operator and line. Remotely manage employee productivity and control scales — changing tolerances, assigning scales to groups, or adding product ID’s.

Added software services

ERP, MRP integration. SQL standard. Doran can ensure that data is fully integrated with ERP, MRP and other enterprise software. All software utilizes SQL Express Database.

On-site support, installation and training

Provided by Doran specialists or authorized Dealer.

![]()

BEYOND INFORMATION, INNOVATION

Doran ionSuite software is easy to configure and easy to operate — delivering real-time data to assess and manage every step of the process for pinpoint control.

Precision performance at every level.

Prompts and process control for measuring ingredients and ensuring user-defined tolerances are met for each ingredient every time. An auto-learning setpoint feature compensates for changing process inputs and the system can interface with existing load cells. The 2200CW provides precision measurements from .01g to 100,000 pounds.

KEY PERFORMANCE FEATURES INCLUDE

Scale Bases

304 stainless steel construction with a Quad-Spring shock-absorbing base design that provides 1000% overload protection in scale bases from 8″ x 8″ to 15″ x 15″ — and provides 300% overload protection in bases 18″ x 18″ and larger.

Rugged design

In a complete 2200CW weighing system, all components act as a defense against the damaging effects of shock, water, abuse, and other environmental factors that can cause costly repairs and production downtime.

Multiple power options

100-240 AC, 50/60Hz line power standard for permanent installation, a high-performance internal rechargeable battery option, or 6-12 VDC input.

Advanced Communications and Control

Connect, control, and communicate to any device or computer with the two standard RS-232 ports, eight standard outputs, two standard inputs, or a wide range of communication options. Connect with our wired Ethernet, Wireless Ethernet, Bluetooth, USB, 4-20mA.

Quality and scalability

Our exclusive Quad-Spring construction, available on DXL Series, delivers 1000% overload protection. Shock overload is transferred to the frame of the scale base protecting the sensitive load cell.

Specifications

| Warranty: | Two Years |

| Power: | 100 - 240VAC 50/60Hz |

| Serial Interface: | Two Bi-directional RS-232 ports |

| Resolution Range: | 200d to 50,000d |

| Number of Load Cells: | Up to 8, 350 Ohm |

| Controls: | Tare, Gross/Net, Zero, Print, Units, Accum, Clear Prod Id, Set Point, Over, Under, Enter, Decimal Point, and Numeric Keypad 0-9 |

| Digital I/O: | Two remote switch inputs, eight digital outputs |

| Temperature Range: | 14° to 140° F (-10° to 40° C) |

| Analog Sensitivity: | 0.16 μV/e min., 0.5 μV/e typical |

| System Linearity: | 0.01% full scale |

| Analog Signal Range: | -0.5 mV/V to 5mV/V 4 and 6 wire input |

| Excitation Voltage: | 5 VDC |

| Construction: | 304 Stainless Steel |

| Base sizes: | 8" x 8", 10" x 10", 12" x 12", 15" x 15", 18" x 18", 18" x 24", 24" x 24" |

| Bracket Weight capacity: | 1 g to 100,000 lb |

| Available Brackets: | U-bracket or Attachment |

| Columns: | 14", 20" and 30" Columns |

Options

| Optional Battery: | Internal rechargeable battery, 60 hrs. of continuous use |

| Optional Communication: | Ethernet, WiFi-802.11b/g, USB, Bluetooth, or 4-20 mA |

| Options: | Super precision calibration Scale veil Internal relays External relays Serial cables Stainless steel load cells Quick disconnects Audible alarms Remote switches Data collection and management software Barcode scanners Label printers Signal light tower |

2200CW Digital Checkweigher Scale

The features and benefits of Doran Model 2200CW digital checkweigh scale explained by Doran CEO, Mark Podl. The 2200CW offers a weighing system that is built to survive in the most harsh working environments, provide extremely accurate weight data, and send that data across a computer network.

Data communications options include:

Two standard RS-232 ports

- Wired Ethernet

- Wireless Ethernet

- Bluetooth

- USB

- 4-20mA

- Fiber Optic

- RS-485

250 Product ID Database

The internal database will store 250 Checkweigh Tolerances, Tare Weights, Accumulation and Counter totals and a description field by a product ID. Handwritten production records to track weighments or accumulated weight are a thing of the past with the 2200CW.

2200CW Checkweigher with QC Weigh

Combining our 2200CW Checkweigh Scale with our QC Weigh provides a complete system that guarantees that QC weight samples are done on a consistent basis. The resulting QC data is much more accurate and reliable than handwritten records. Our CEO, Mark Podl, explains how this system works.