Available scale data communications options

- Bluetooth

- Wired

- Ethernet

- Wireless

- Ethernet

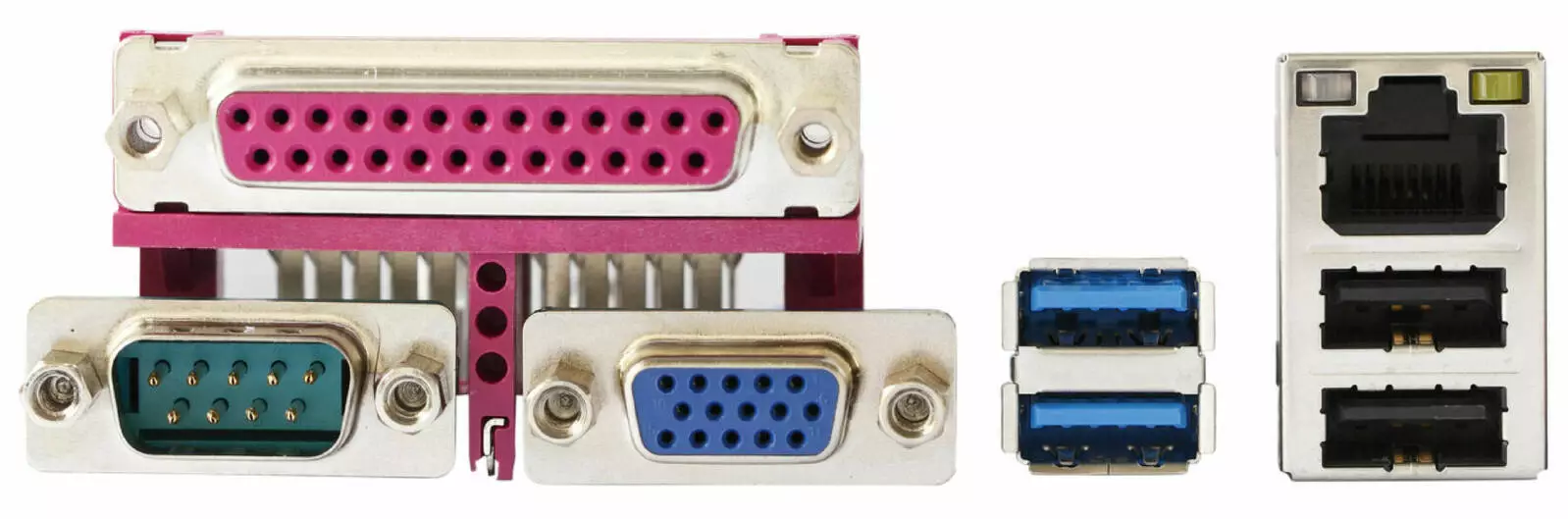

- USB

- RS-232 4-20mA

Dimension Indicator Configuration Software

Dimension software adds an extra dimension to configuring Doran indicators.

LEARN MORE ABOUT DIMENSION SOFTWARE

Complete connectivity solutions.

Equipment + software.

Benefits of USB communications

With Doran’s Excel Series Indicators line comes an array of “Value Added Standard Features and Options” for a wide variety of applications. With that in mind, Doran is now able to provide a solution for customers requiring USB communications.

In the scale industry, the RS232 Serial Port has been used for communications between scales, computers, or printers since the introduction of the personal computer. In 2002, PC manufacturers agreed to obsolete Serial Ports over time and replace them with USB communication ports. Therefore, today’s computers are not always equipped with an RS-232 port, which makes the use of USB absolutely necessary.

There are several benefits to using USB communications over RS232 Serial Ports. These include ease of use, reliability, flexibility, and compatibility.

When a USB device is connected:

There is not a requirement to configure any communication settings before using the device

- USB hubs are available for expandability up to 127 USB devices per PC

- USB cables and components are common and inexpensive, keeping user costs to a minimum

- Windows™ Operating Systems automatically detect the USB device and will prompt the user to install a device driver if necessary

Doran has responded to this industry trend by introducing the USB option for our Excel Series Indicators. USB allows a PC to monitor several scales at once, utilizing included USB ports on the PC or through USB hubs, which expands the number of USB ports available. Our USB option utilizes a driver that allows the USB port to be recognized by the PC as a Serial Com Port. This allows the end user to view and collect data easily, using standard terminal or data collection programs such as our Excelerator Data Acquisition Program.

As with all Excel Series communications options, the USB option exceeds the NEMA 4X and IP67 washdown standards. A bulkhead connector at the rear of the scale, along with Doran’s optional USB cables, provides a rugged and reliable USB cable connection. A mating cap is molded to the USB cable and screws into place, sealing and solidly holding the USB connection (see photo). A protective cap is included at the rear of the indicator to provide washdown protection when the mating USB cable is disconnected. We offer a 6-foot and a 16-foot cable that includes these washdown features. The USB standard limits cable length to 16 feet, although a maximum distance of 96 feet can be achieved with the use of five USB hubs connected in series.

Sample application

One computer receiving data from five scales into an Excel spreadsheet via USB: A customer needed to collect QC data to monitor his production line. The customer wanted to collect data with a single PC into an Excel spreadsheet from five scales simultaneously. This user did not have an RS232 port on his PC and wanted to invest in a five-port RS232 expansion board. This customer also did not have an Ethernet network to which he could connect the scales. A new 7000XL with the USB option was the most economical and convenient solution for this application.

To allow five scales to be connected via USB to a PC at one time, a five-port USB hub was purchased. This hub is connected to each of the five Doran 7000XL Indicators via a USB cable. In order to sort the data in the Excel spreadsheets at a later time, a custom data string was created using the Doran Dimension Indicator setup software. Each scale had a data string that included a scale ID and the current weight and units. Once configured, Doran’s Excelerator Data Collection Software sent data from the scales directly into the Excel spreadsheet, with each scale sending data to a different sheet in the workbook. Since Excelerator automatically sent data into Microsoft Excel, the data could be immediately analyzed to determine the precision of the QC sample from the manufacturing line. The customer could now control his line process with a ten-piece sample from his line three times daily and make equipment control adjustments when necessary.

Benefits of RS-232 communications

RS232 is the most commonly used and economical communication interface for sending scale data to another device (such as printers, PCs, remote displays and PLC controllers). Doran includes RS232 as a standard feature in all of our products.

INSTALLATION

For washdown applications, the optional RS-232 cable is passed through a bulkhead mounted watertight, fitting to retain washdown protection. RS-232 communications is a simple communications standard requiring a single cable with three conductors, one each for TXD – Transmit, RXD – Receive and GND – Signal Ground. The maximum length for a cable run is 50 feet, which may be reduced based on electrical and RF noise present in the application environment. When using RS-232, the correct interface cable is necessary for communication between the scale and the other device. Most serial devices utilize a 9-pin D style connector. It is important to determine how the external device will need to receive the scale data. Available communication settings are:

Transmit on Demand – The scale transmits data to the external device each time the PRINT button is pressed. This is typically used for manual operations like sending data to a barcode label printer as a product is weighed and then labeled.

Continuous Transmission – In the continuous mode, each displayed weight is transmitted to the external device. A constant update of the weight on the scale is required for data collection or system control applications. In these applications, the real-time weight data is logged to a data collection program like Doran’s Excelerator or used by a PLC for system control.

Auto Transmit – This allows for automatic transmission of scale weight data when a stable weight registers on the scale. Once the weight data is transmitted, the scale will not transmit again until the weight is removed from the scale. This allows the user to concentrate on the product, while data is automatically transmitted to a PC data collection program like Doran’s Excelerator or a barcode label printer.

Sample applications

Labeling boxes for palletizing and printing a total pallet weight label

In this application, the scale will be configured for an automatic print. When each box to be packaged together on a pallet is placed on the scale, the weight data is sent to a label barcode printer and added to the weight accumulator automatically when a stable weight is achieved. The printed label is applied to each individual box, with weight, date, barcode label, custom graphics, and a description of the contents. Once the entire pallet is ready for shipment, a total weight label can be printed; the label will contain the weight and count of each box weighed and placed on the pallet for use in the shipment bill of lading and in inventory control.

Using a personal computer to log weight data to an Excel spreadsheet

Weight data can be sent to a computer using the standard RS-232 feature, along with an optional serial cable. This allows for the automated recording of real-time production data. Manual recording of weight data to a paper log can be time-consuming and error-prone as data points can be missed. Typing data into a spreadsheet at a later time riskily relies on the correct interpretation of handwritten data. Automated data acquisition is easily implemented with Doran’s Excelerator Data Collection Software. Once Excelerator is configured, all transmitted weight data, units, and product ID are automatically inserted into a Microsoft Excel spreadsheet. Other data points, such as time and date, can be added automatically, allowing data to be immediately examined with statistics and user-defined graphs. All this information can be archived for later analysis, billing information, or historical records.

Wired and Wireless Ethernet Communications Options – Advantages and Disadvantages

Virtually every company today has an Ethernet network to distribute email, provide Internet access, share printers, and run enterprise wide software. Your customers both large and small can leverage their existing Ethernet and PC hardware infrastructure and extend it to the factory floor. The merging of the administrative, control level, and device level networks makes for a less expensive and more connected data network. The result is an efficient end-to-end flow of data from the plant floor to the front office network, where it can be used to better manage operations.

Adding scales to an existing Ethernet network will not adversely affect the network speeds for existing devices. The speed of 10/100Base-T Ethernet networks that provide up to 100 Mbps communication bandwidth clearly eclipses the requirements for scale communications. A typical scale data string only requires about 200 bits, a tiny fraction of the available bandwidth for Ethernet.

As an example of the speed of Doran’s Ethernet option; The Excelerator Data Collection Software can monitor up to 20 scales with continuous print into one spreadsheet workbook in real time, while only utilizing 0.004% of the total network’s Ethernet bandwidth. Compare this to loading Google on Internet Explorer, which requires quite a bit more network bandwidth! Utilizing the existing Ethernet network without affecting existing devices makes Doran’s Ethernet communications option extremely cost effective. It is obvious that RS-232, with all of its networking and configuration drawbacks, is quickly becoming a communications method of the past for data collection.

Is Ethernet Expected to see Continued Strong Growth and Acceptance?

Ethernet enjoys this wide acceptance because it is easy to understand, deploy, manage, and maintain. Since Ethernet is vendor independent, it provides economies of scale and vast technological innovations. Implementation of a system is very cost effective considering that the infrastructure can be shared with an existing network as well.

The cost effectiveness of Ethernet is expanding the data collection market. Ethernet is an accessible option for customers who previously did not have the expertise or the budget to implement an industrial data collection or PLC system. Proprietary PLC systems are losing market share to Ethernet not only because of implementation costs but also because of Ethernet’s increased functionality. PLC architectures are being replaced in many applications by Ethernet. And due to Ethernet’s wide acceptance, the number of devices and software that can interface with Ethernet devices is several magnitudes larger that PLC-based systems.

Why Consider Doran Ethernet for Scale Communications?

When data is collected from a scale or from multiple scales, it fundamentally increases the value of the weighing system. It is no longer “just a scale,” it is now an efficiency meter, providing accuracy verification and serving as a productivity aid. Real-time data from the scale is valuable, and Doran’s Ethernet and data collection systems make it easy to take advantage of this data. The Doran Ethernet open-standard networking solution securely connects the factory to the corporate office, enabling organizations to make strategic business decisions backed by real-time data from the production floor. Doran has been working with Ethernet applications for over five years. During this time we have amassed a significant wealth of experience.

What are Potential Problems?

Developing and facilitating a working relationship through open lines of communication with IT personal and plant or control engineers is not always an easy task. Many companies with politically strong IT departments may derail an Ethernet application because they don’t understand the need and benefit, or because they are just too busy to be bothered with it. The key to acceptance and successful implementation of scale Ethernet systems is to provide outstanding support to the plant engineers.

Many plants are already online with Ethernet and are ready to take on the implementation task from a plant manager–level without involving IT. But due to security concerns and sometimes complex configuration, Wireless Ethernet is still mainly handled by IT departments.

There are many different networking hardware providers and each uses their own security terminology and operates slightly differently. As a result of this diversity and complexity (e.g., Cisco routers have a 200+ page manual vs. a Linksys 10 page manual), we have found that Wireless routers are difficult for Doran to troubleshoot remotely. It is especially difficult if the IT personnel don’t spend time configuring the access point security settings to complete the scale installation. When the customer has not been able to get the IT department involved, we have suggested alternate routers that we have successfully worked with in the past. While no one may be interested in stealing weight data from a scale, a breach of the wireless access point security would give an unauthorized user complete access to a customer’s server and Internet. In many cases, this risk is too great to just hand over to a non-IT professional.

The reliability of Ethernet networks is very high, but if this network goes down it may hamper production, particularly if control systems are implemented through the company-wide network. Networks and servers are constructed with redundancies even at the device level to prevent outages, but outages do need to be taken into account when designing an Ethernet-based control system.

Which is Better, Wired or Wireless?

A basic rule to consider: If there is a potential safety issue involved, or if the data absolutely critical and every effort must be made to safe guard it, use Wired Ethernet. If that is not the case, consider these advantages and disadvantages for wired and wireless Ethernet:

Wired Ethernet Advantages

- Easy to implement: plug in and you are ready to go

- Many non-IT professionals can implement the installation

- Easy to troubleshoot the network connection and cabling

- Status lights on the Ethernet option and Ethernet Switch indicate the status of the network connection and cable integrity

- Cable connection to the scale is IP65-rated

Wired Ethernet Disadvantages

- Requires cables to be run, which can represent up to 50% of the device’s installation

- Harsh environments require hardened cabling with polyurethane jackets that resist oil, caustic cleaners, and harsh environments

- If equipment leaves the room for the washdown, the connector on the Ethernet cable will need to be protected when not connected to the scale.

Wireless Ethernet Advantages

- No cables to run, reducing initial device installation time

- Scales can be easily moved from one location to another in the plant while maintaining communications

- The plant can be reconfigured without concern for Ethernet cables

- Antenna is IP65-rated

Wireless Ethernet Disadvantages

- Usually requires the IT department to get involved in order to ensure proper security configuration

- Many companies have chosen not to implement wireless Ethernet

- Security settings on the wireless router and the scale must be properly configured initially. This process is made easier with two wireless routers and previous implementation experience

- Security settings need to be reconfigured on a regular basis to ensure network security, which raises long-term network maintenance costs

- Difficult to remotely implement; difficult for non-IT professionals to properly configure and to understand the settings for highly sophisticated WAPs

- Equipment, walls, or other RF based devices can interfere with wireless signals.

Benefits of Fiber Optic communications

Doran’s Fiber Optic Option provides full duplex bi-directional serial data communications for: Intrinsically Safe (IS) Hazardous areas Applications that require communications over distances up to 1000 ft Applications with severe electrical or RF noise. Communication standards like USB, RS-232, and Ethernet require copper cable with a voltage potential to transmit data between two devices. Fiber optics utilizes light to accomplish the same task. Fiber optic cable is made of a transparent glass core surrounded by a mirror-like covering, enclosed inside a fire-resistant outer jacket. Light passes through the cable, bouncing off the mirror covering until it reaches the other end of the fiber optic cable.

Fiber optic communications is widely used in IS Hazardous environments due to the convenience of installation and use. In an IS environment, copper cables carrying a voltage or current potential are often required to be installed into conduit; this ensures safety in a hazardous environment, but it also increases installation and maintenance costs. In hazardous IS environments, fiber optic cables can be run without the need for conduit which speeds the installation process. Doran’s 9000XL IS indicator utilizes fiber optic communications for data transmission and I/O control for relay control and remote signal inputs. Fiber optics are also available as a standard option in Doran’s line of Excel Series indicators for non-IS environments. Fiber optic communications completely eliminate electrical and radio frequency noise. Long runs up to 1000 ft are much more convenient, less costly to install, and easier to maintain with fiber optics as signal boosters. Additionally, repeaters are not required.

Sample application

A customer needs to weigh 35 lbs of oil-based paint mixture in a hazardous area and needs to send the production weight data to a safe area computer. All scale components must be explosion-proof and meet FM (Factory Mutual) Intrinsically Safe criteria. Enter the Doran 8200IS Intrinsically Safe Indicator, with a 12” x 12” DXL 50 lb scale base containing an FM Approved load cell. Doran’s Guardian 9000XL/IS is an approved Factory Mutual System.

The Fiber Optic Option is ordered with the AC Line Guardian 9000 XL/IS Scale System along with the fiber optic Converter that provides RS-232 communication to the safe area computer. A 50-ft fiber optic cable is included with the order of this interface. The fiber optic cable is run to the safe area computer. The Fiber Optics Converter is installed, providing interface from fiber optic to RS-232 to the computer.

For data acquisition, Doran’s Excelerator Data Collection Software is a great way to collect weight data for archiving and future review. Once Excelerator is up and running, the user will weigh the 35 lbs of paint mixture and press the Print button. This will send the weight and unit to the computer running Doran’s Excelerator program.