Precision automation. Actionable information.

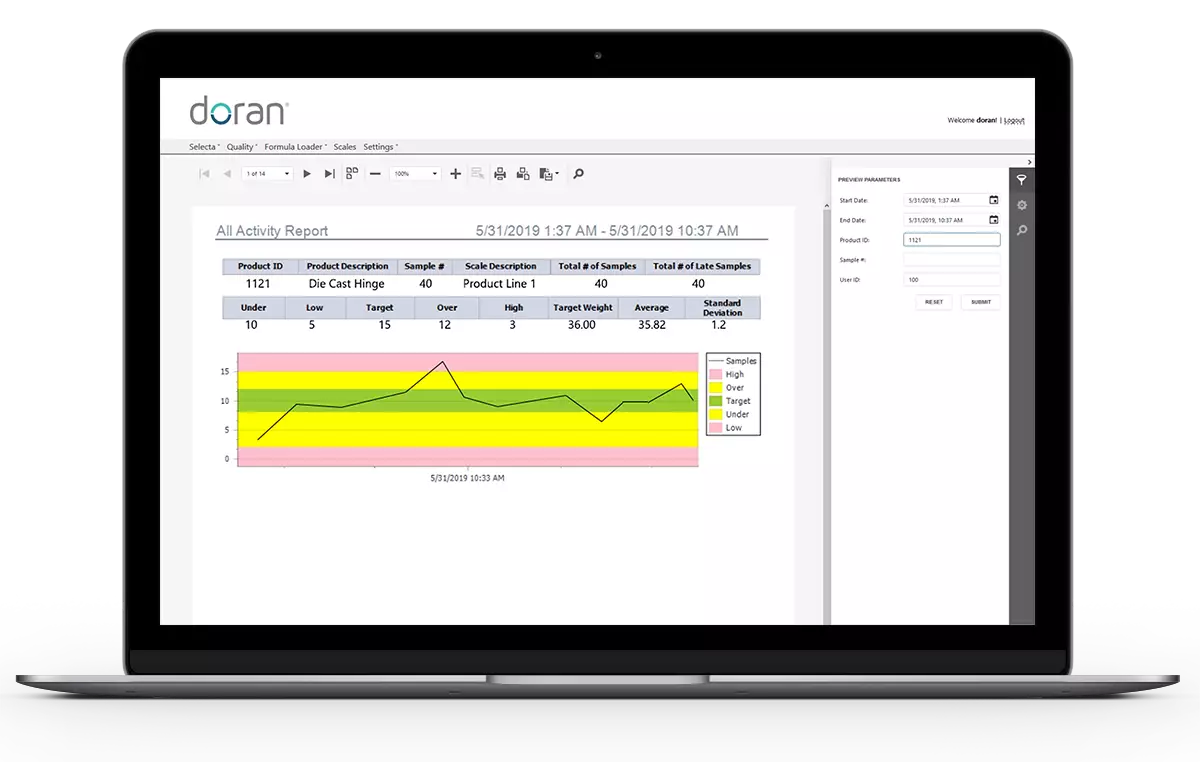

QC Weigh captures quality control data from Doran 2200CW Checkweighers, so managers and operators can ensure accurate product weights and meet QC benchmarks. This level of precision control is also vital for meeting regulatory requirements, third party food safety standards and quality control certification programs. In addition, QC Weigh data can improve accountability, using unique operator ID’s and scheduled sample intervals to ensure that employees are performing quality control tasks. Compared to handwritten QC records, QC Weigh delivers accurate information in real-time — to pinpoint manufacturing issues, improve productivity and lower production costs.

KEY PERFORMANCE FEATURES INCLUDE

Real-time data collection and efficient production

Pinpoint control of the plant floor.

Employee accountability

Gather data at every step of the process to ensure user-defined tolerances are met for each ingredient every time.

Desktop, laptop or mobile accessible with any browser

Communication connection with 2200CW include wired Ethernet, washdown safe Ethernet, Bluetooth or USB.

Cloud-based or install on premise

With access from internal systems.

Effortless configuration

Configure QC Weigh and the 2200CW with drop-down menus and easy-to-understand program prompts.

Configure several scales with identical data

Programming hundreds of product parameters takes minutes, instead of hours.

![]()

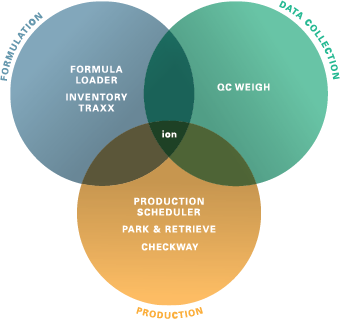

BEYOND INFORMATION, INNOVATION

Doran ionSuite software is easy to configure and easy to operate — delivering real-time data to assess and manage every step of the process for pinpoint control.

Exclusively for the Doran 2200CW Checkweigher Series

QC Weigh is designed for the 2200CW, a versatile checkweigher that delivers for speed, durability, and versatility. From the Master Product list, simply enter the Product ID, Description field, Checkweigh parameters, and Tare weights and then select the scale or scales to upload to or download from. Available management reports organized by product line, sample number, and product can be generated at pre-determined intervals. The 2200CW has memory for 800 product IDs and 200 user IDs.

QC WEIGH SOFTWARE

Reports organized by product line, sample number, and product can be sent by email to provide a snapshot of daily production performance.

ADDITIONAL SOFTWARE AVAILABLE FOR 2200CW

Performance ID software

Record all weighments on the factory floor and view performance by product, operator and line. Remotely manage employee productivity and control scales — changing tolerances, assigning scales to groups, or adding product ID’s.

Enterprise software integration. SQL standard

Doran can ensure that data is fully integrated with Statistical Process Control (SPC) systems and other enterprise software. All software utilizes SQL Express Database.